A Unique Rubber Band Powered Kid’s Toy Car

The client, Spin Master, has requested the design of a rubber band-powered toy car for children that costs <$15 to manufacture and can travel a minimum of 20 ft while maximizing its average speed. Existing toy car competitors in this price range either cannot cover distances of 20 feet or do so very slowly, leaving a gap in the market. To address this lack of low cost higher speed cars, the team has developed a design leveraging crank input to torsion a rubber band. In this design, the torsioned band powers the car’s rear wheels through two perpendicular pulleys connected by another rubber band, which causes the car to move forward with high speeds.

Project Requirements

Benchmarking and Positioning

Final Design Working Principle

Control Factors and Noises

Design of Test Rig

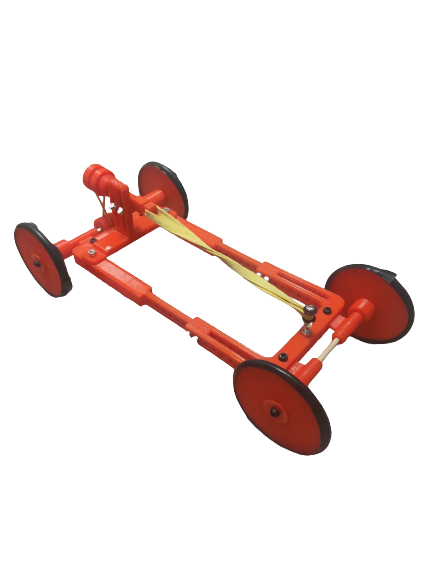

To optimize this design, the team designed and assembled a test rig. This rig was used to analyze four three-levelled control factors: wheel diameter, number of rubber bands to be torsioned, rubber band extension length, and distance between the perpendicular pulley.

3D Printed Test Rig

Experimental Design

A Taguchi L9 matrix was selected to investigate the experimental runs in order to optimize for time and cost of experiments. Surface roughness was considered as a noise factor of two levels; level 1 comprised smooth wooden surfaces while level 2 comprised rough tiled surfaces. The average speed in covering 20 feet was measured as the output response for each experiment.